FAQ : our answers to your questions

Do you have a question?

Here you'll find answers to frequently-asked questions.

If you don't find an answer, please don't hesitate to contact us.

The soils and material we accept:

The only spoil that comes to our sites is 'inert material' as defined by Article R541-8 of the Code de l'Environnement.

95% of the materials used on ECT's land-use development site are inert soils. The other 5% also consist of inert materials - stones, aggregate and concrete - that are used to construct and maintain the site roads. These materials are categorised as 'inert' because they have not been subjected to any significant physical, chemical or biological modification; they do not decompose; they don't burn; they don't produce any physical or chemical reaction; they are not biodegradable, and they do not cause materials with which they enter into contact to deteriorate in a way that may harm the environment or human health.

Complete table of inert materials

| WASTE CODE | DESCRIPTION | |||||||

|---|---|---|---|---|---|---|---|---|

| INERT SOILS |

|

|

||||||

| NON-POLLUTED RUBBLE |

|

|

||||||

| WET SOILS | 17 01 02 |

|

||||||

| Blocs | 17 01 01 | Concrete, rock |

What materials are rejected at the entrance to ECT sites?

All non-inert materials are forbidden on our sites. That includes:

Wood, whether treated or not; metals, plastics, bulky waste, tires, insulation material with or without asbestos, plaster, textiles, glass, waste packaging, green waste from plants/vegetation, topsoil, tar and tarred products, asbestos, paint residues, adhesives and mastics with solvents or containing heavy metal oxides, soot, acid and base soils, polluted rubble, slag and polystyrenes.

'Inert materials' are defined by Article R541-8 of the French Code de l'Environnement.

They are materials that do not undergo any significant physical, chemical or biological change. Inert materials do not decompose, burn or produce any other physical or chemical reaction. They are not biodegradable and do not cause deterioration of other materials with which they enter in contact in such a way as to lead to pollution of the environment or harm to human health (Council Directive 1999/31/CE of 26 April 1999 - EU Official Journal of 16 July 1999).

It is forbidden to dilute or mix waste for the sole purpose of satisfying the admission criteria (decree of 28 October 2010).

A regulatory procedure

Our customers in the construction & public works sector are required to send us a request for prior approval (Demande d'Acceptation Préalable or DAP) before their first deliveries of inert materials.

This document states:

- The geographical origin / location of the site of origin

- The producer's contact details

- The haulage contractor's contact details

- The type of spoil and the amount

This information is then compared with the database of potentially contaminated sites in the Île-de-France region (BASOL).

A separate DAP is needed for each 'donor site' (site of origin). If there is no DAP, the soil will not be accepted at ECT's development site. DAP requests must be sent at least 48 hours before the first deliveries, to the following email address: dap@groupe-ect.com

The preliminary check - the DAP

As a first step, every company that wants to bring soil or materials from a particular site must send a request for prior approval (Demande d'Acceptation Préalable or DAP) to ECT's Quality department.

This document states:

- The geographical origin / the location of the site of origin

- The producer's contact details

- The haulage contractor's contact details

- The type of spoil and the amount

This information is then compared with the database of potentially contaminated sites in the Île-de-France region (BASOL). If pollution is suspected, preliminary samples of the material will be requested. A separate DAP is needed for each 'donor site' (site of origin) of each ECT customer. No material is accepted without the prior agreement of the Quality department, which is responsible for ensuring compliance with the classes of materials accepted at the site concerned.

Dowload the various ECT DAP forms

On-site checks

These controls are required by the provisions of Article 19 of the order of 12 December 2014 by the Ministère de l’Écologie in relation to facilities for disposal of inert waste, which states:

"The direct discharge of waste into the final disposal zone is forbidden. There is to be a waste checking zone so that the waste can be checked after it is emptied from the trucks that transport it. This zone may be relocated at different phases of operation of the site. There shall be particular signage for this zone and its extent, making it possible to locate it.

A truck may not be discharged in the absence of the site operator or his representative ".

Upon receipt of a load at the site, a construction & public works site 'waste tracking document', setting out the information from the DAP and information about the haulage contractor and his registration number, shall be provided to the site reception officer responsible for checking the quality of the materials. The data in this waste tracking document shall be entered in an admissions register, sent daily to ECT headquarters.

For every load presented, there shall be recorded:

- The date and time it was received

- The origin and nature of the materials

- The volume of the materials

- A check of the accompanying documents and the DAP

- When appropriate, a video recording of the check

- The registration number of the vehicle and the haulier's company name or trading name

- If appropriate, the reason for refusing admission. If pollution or unauthorised materials are noted, the load will go on its way after having been recorded in a register kept for this purpose (date and time of refusal, the vehicle registration number, the name of the producer and of the haulier, the exact address of the site of origin, the nature and quantity of the material, and the reason for refusal). These refusals are put into a declaration that is forwarded to the regulatory authority at regular intervals.

The materials are then unloaded near the area of the site that is currently being filled, and they are handled by a bulldozer responsible for placing the inert material. The bulldozer driver carries out a second waste check. A third and final check is carried out when the material is spread out before being put into the landfill by the bulldozer driver.

If pollution is suspected, the materials are reloaded. When this happens, it is recorded in the register of refusals.

From the computerised register of admissions, it is possible to see exactly which customers and which construction sites have discharged materials at the site and to produce a monthly 'waste traceability document' (a Bordereau de Suivi de Traçabilité) for each customer and/or site. Also, a topographic plan is kept and updated which makes it possible to identify the zone and level in the landfill that corresponds to the figures given in the register.

External checks

Departments of the local authorities concerned are invited to all site meetings and can carry out any checks they like.

In the context of ISO 14001 certification (applicable since December 2011), ECT's sites are subject to regular random checks by an independent auditor who checks that all the applicable regulatory requirements for facilities of this kind are being complied with.

ECT is also subject, on all its sites, to regular checks by inspectors from the regulatory authorities (the DRIEE and the DDT) in charge of sustainable development. They make unannounced visits to sites to check for compliance with the relevant statutes and regulations.

Limiting the environmental impact

In the context of its ISO 14001 certification, which was renewed in 2020, ECT, as part of a process of continual progress, has put in place various means of limiting the environmental impact of its work.

All the operational ECT sites are ISO 14001 certified.

See the ISO 14001 certification

Optimised coverage by the sites

The sites operated by ECT are of two kinds, for an optimised network for transport of inert soil:

- A network of smaller sites that can receive several hundred thousand cubic metres of materials from local deposits. This network, which is gradually extending to cover the whole of the Île-de-France region, makes it possible to reduce the length of travel by trucks and thus to contribute to a smaller carbon footprint by reducing emissions of greenhouse gases.

- Large sites like the one at Villeneuve-sous-Dammartin (77) that can receive millions of cubic metres of materials and can deal with the very large number of trucks from major earthworks projects in the Île-de-France

We work systematically with the businesses in charge of projects to prepare, with them, solutions making it possible to limit environmental impacts, in particular by choosing a suitable "receiver site". Access routes to dumping zones are mainly via major roads, so as to limit as far as possible the inconvenience caused to nearby residents.

Dealing with dust and mud

In compliance with regulations about keeping public highways clean and the dispersal of dust, ECT ensures that, on all its development sites, the site and all public access roads are kept clean throughout the period of development works. Depending on the size of the site, there may be a truck wheel washing system installed at the site exit.

During dry periods, the site roads and the zones being filled are sprayed with water if necessary. The site access roads are regularly cleaned by a road sweeper.

Dealing with noise nuisances

In compliance with Article R 48-5 of the French Code of Public Health relating to the fight against local noise, ECT takes every care to organise the operation of its development sites so as to limit nuisance noise, and sees that its equipment gets regular maintenance.

Protection of water

Because the materials brought to the site are inert, ECT's development projects do not present any risk of pollution of surface water or groundwater.

If necessary, a hydrological study is carried out so as to direct and manage site runoff.

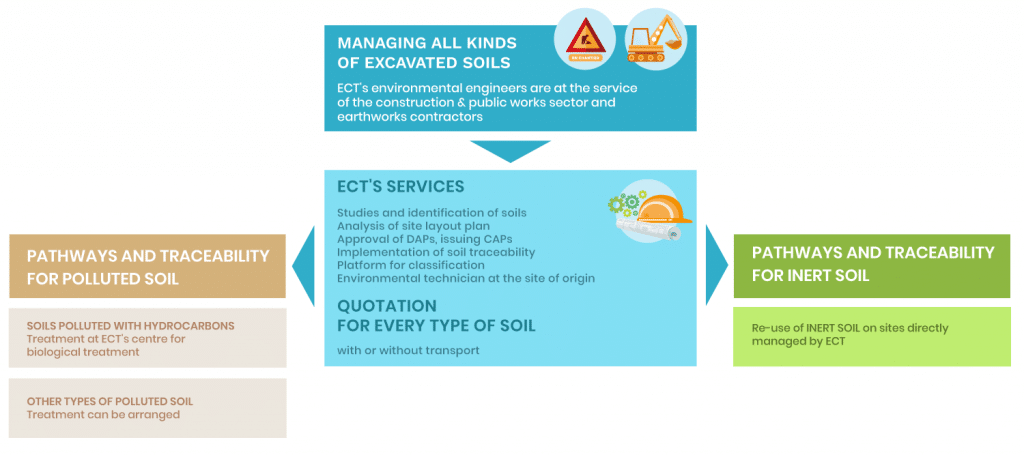

ECT is a one-stop service for recycling soil from construction sites

ECT offers its customers in the construction & public works sector a single point of contact for the management of all soils from building sites and public works. ECT's Environment / Soil Management department provides customers with effective solutions to their need for environmental engineering expertise, and the requirement for traceability from the construction & public works sector including the Grand Paris Express.

The skills and experience of this department allow it to set out a pathway for the various types of excavated soil (in class 2 or class 3) from every construction site, by applying the required traceability procedure for each type.

- Inert materials follow a pathway that allows for them to be directly re-used on ECT development sites.

- ECT also has a site for biological treatment of soil polluted with hydrocarbons. This centre, at La Courneuve (93), underpins ECT's ability to manage all soil excavated by the construction & public works sector by offering an effective outlet for soil polluted with hydrocarbons.